5 Key Facts About Spring Constants

Fact 1: The Definition of Spring Constants

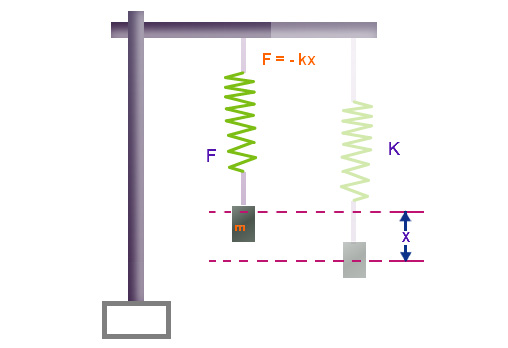

A spring constant, denoted by the symbol $k, is a measure of the stiffness or rigidity of a spring. It quantifies the force required to extend or compress a spring by a certain distance. Mathematically, the relationship between force (F), displacement (x$), and spring constant is described by Hooke’s Law:

\[ \begin{equation*} F = -kx \, . \end{equation*} \]

This equation illustrates that the force exerted by a spring is directly proportional to the displacement from its equilibrium position and inversely proportional to the spring constant. In simpler terms, springs with higher $k values are stiffer and require more force to deform, while those with lower k$ values are more flexible and deform more easily.

Fact 2: Units and Standard Values

Spring constants are typically measured in units of force per unit length, such as $\text{N/m} (Newtons per meter) or \text{lb/in} (pounds per inch). These units represent the force required to stretch or compress a spring by one unit of length. Common values for spring constants can vary significantly depending on the type of spring and its intended application. For example, in automotive suspension systems, spring constants can range from hundreds to thousands of \text{N/m}, while in smaller precision instruments, they may be in the range of \text{mN/m}$ (milli-Newtons per meter).

Fact 3: Impact on Spring Behavior

The spring constant directly influences the behavior and performance of springs in various mechanical systems. Springs with higher $k values offer greater resistance to deformation, making them suitable for applications that require stability and controlled movement, such as shock absorbers in vehicles or support systems in buildings. On the other hand, springs with lower k$ values are more compliant and provide smoother, more flexible responses, making them ideal for applications like suspension systems in bicycles or mattresses.

Fact 4: Calculating Spring Constants

Determining the spring constant of a specific spring involves applying Hooke’s Law and measuring the force required to achieve a known displacement. This can be done experimentally by attaching weights to the spring and measuring the resulting extension or compression. The spring constant can then be calculated using the formula:

\[ \begin{equation*} k = \frac{F}{x} \, . \end{equation*} \]

For complex spring systems or those with nonlinear behavior, more advanced techniques, such as mathematical modeling and finite element analysis, may be necessary to accurately determine the spring constant.

Fact 5: Applications Across Industries

Spring constants find extensive applications across diverse industries. In automotive engineering, they are crucial for designing suspension systems that provide a comfortable and controlled ride. In the field of robotics, spring constants are used to control the stiffness and responsiveness of robotic joints. Additionally, spring constants play a vital role in medical devices, such as spring-loaded syringes and implantable devices, where precise force control is essential. The understanding and manipulation of spring constants are also integral to fields like materials science, biomechanics, and even musical instrument design.

How does temperature affect the spring constant of a material?

+Temperature can significantly impact the spring constant of a material. In most cases, an increase in temperature leads to a decrease in the spring constant. This phenomenon is attributed to the thermal expansion of the material, which causes the spring to elongate and become less stiff. Conversely, a decrease in temperature can result in an increase in the spring constant as the material contracts, making the spring stiffer.

Can the spring constant be adjusted after a spring is manufactured?

+Yes, the spring constant of a spring can be adjusted post-manufacturing through a process known as stress relief or tempering. By subjecting the spring to specific heat treatments, engineers can alter its internal structure, effectively changing its stiffness. This technique is particularly useful in industries like aerospace, where precise control over spring constants is critical for safety and performance.

What happens if a spring's displacement exceeds its elastic limit?

+If a spring is displaced beyond its elastic limit, it undergoes plastic deformation. This means that the spring permanently deforms and loses its ability to return to its original shape. In such cases, the spring may become damaged, rendering it unsuitable for its intended purpose. It is crucial to design springs with appropriate spring constants and limits to ensure their safe and effective operation.

In conclusion, spring constants are fundamental parameters that govern the behavior of springs in mechanical systems. Understanding their role, units, and applications across industries is essential for engineers, physicists, and designers working with spring-based systems. By harnessing the power of spring constants, professionals can create innovative solutions, optimize performance, and ensure the reliability of a wide range of mechanical devices.