Essential Tips for Sodium Hydroxide Safety

Sodium hydroxide, often referred to as caustic soda or lye, is a highly versatile and commonly used chemical compound. However, its powerful nature demands utmost respect and careful handling to ensure safety. In this comprehensive guide, we delve into the essential tips and practices to safeguard yourself and your environment when working with sodium hydroxide.

The Importance of Safety Protocols

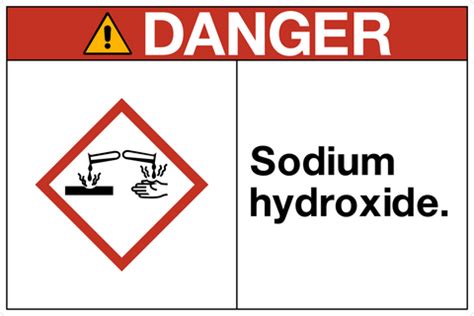

Sodium hydroxide is a corrosive substance that can cause severe burns to the skin, eyes, and respiratory system if not handled properly. Its strong alkaline nature means it can react violently with certain materials, leading to unexpected and potentially hazardous outcomes. Therefore, it is crucial to prioritize safety at every stage of handling, from procurement to disposal.

Here’s a detailed breakdown of the safety measures you should adhere to:

Personal Protective Equipment (PPE)

Wear Chemical-Resistant Gloves: Choose gloves made from materials like nitrile, neoprene, or butyl rubber, which offer excellent protection against sodium hydroxide. Ensure they fit snugly and are free from punctures or tears.

Eye and Face Protection: Always wear safety goggles or a face shield to safeguard your eyes and face from splashes or sprays. In case of dust or aerosol generation, consider using a full-face respirator.

Protective Clothing: Opt for long-sleeved shirts and pants made from materials like polypropylene or cotton to cover your skin. Avoid wearing clothing made from materials like nylon or polyester, which can easily melt if exposed to sodium hydroxide.

Respiratory Protection: In well-ventilated areas, a simple dust mask may suffice. However, if you’re working in a confined space or with large quantities of sodium hydroxide, use a respirator with appropriate cartridges to protect against inhalation.

Safe Handling and Storage

Always Read the Label: Before handling sodium hydroxide, carefully read the product label and Safety Data Sheet (SDS) to understand its hazards, proper handling procedures, and first-aid measures.

Handle with Care: Treat sodium hydroxide with respect and avoid any unnecessary contact. Use appropriate tools, such as long-handled scoops or tongs, to handle the substance.

Storage Considerations: Store sodium hydroxide in a cool, dry, and well-ventilated area, away from incompatible materials like strong acids or oxidizing agents. Ensure the container is tightly sealed and clearly labeled.

Emergency Preparedness

Have an Emergency Plan: Develop a comprehensive emergency response plan that outlines the steps to take in case of spills, fires, or personal exposure to sodium hydroxide. Share this plan with all relevant personnel.

Spills and Clean-Up: In the event of a spill, act quickly and follow the instructions on the SDS. Use absorbent materials like vermiculite or sand to contain the spill. Avoid using water directly on sodium hydroxide spills, as it can generate heat and cause splashing.

First-Aid Measures: Familiarize yourself with the appropriate first-aid procedures for sodium hydroxide exposure. In case of skin or eye contact, flush the affected area with water for at least 15 minutes. For inhalation or ingestion, seek immediate medical attention.

Disposal and Environmental Impact

Responsible Disposal: Never dispose of sodium hydroxide down the drain or in regular trash. Consult with your local waste management authorities to determine the appropriate disposal methods, which may involve neutralization or specialized waste collection.

Environmental Awareness: Sodium hydroxide can have significant environmental impacts if not handled responsibly. Ensure you understand the potential effects on aquatic life and take steps to minimize any negative consequences.

Training and Education

Stay Informed: Continuously update your knowledge about sodium hydroxide safety. Attend training sessions, read relevant literature, and stay connected with industry professionals to stay informed about best practices and emerging safety guidelines.

Empower Your Team: If you’re responsible for overseeing others who work with sodium hydroxide, ensure they receive adequate training and are aware of the potential hazards. Regularly conduct safety drills and refreshers to maintain a culture of safety.

Expert Perspective: Insights from Industry Professionals

“Sodium hydroxide is a powerful tool in many industries, but it’s not something to be taken lightly. The key to safe handling is education and respect for the substance’s potential hazards. By staying informed and implementing robust safety protocols, we can minimize risks and create a safer working environment.” - Dr. Emily Williams, Industrial Chemist

“One often-overlooked aspect of sodium hydroxide safety is its potential impact on the environment. Responsible disposal and proper handling can make a significant difference in protecting our ecosystems. It’s a collective responsibility to ensure we use this chemical responsibly.” - Dr. David Chen, Environmental Scientist

Practical Application: A Step-by-Step Guide to Safe Handling

Here’s a step-by-step guide to help you handle sodium hydroxide safely:

Put on your PPE, including gloves, eye protection, and protective clothing. Ensure your respirator is properly fitted and ready for use.

Carefully open the container of sodium hydroxide, being mindful of any potential pressure build-up.

Transfer the required amount of sodium hydroxide to your work area using appropriate tools. Avoid any unnecessary contact with the substance.

Work in a well-ventilated area, and if necessary, use a fume hood or other ventilation system to control airborne contaminants.

When you’re finished with your work, carefully return the remaining sodium hydroxide to its storage container, ensuring it is securely sealed.

Dispose of any waste materials or contaminated PPE according to your organization’s protocols and local regulations.

Always wash your hands thoroughly after handling sodium hydroxide, even if you’ve worn gloves.

Remember, safety should always be your top priority when working with sodium hydroxide. By following these essential tips and staying vigilant, you can minimize risks and create a safer environment for yourself and those around you.

The Future of Sodium Hydroxide Safety: Emerging Trends and Technologies

As industries continue to rely on sodium hydroxide for various applications, ongoing efforts are being made to enhance safety measures and minimize potential hazards. Here are some emerging trends and technologies shaping the future of sodium hydroxide safety:

Advanced PPE: Manufacturers are developing innovative materials and designs for personal protective equipment, offering enhanced protection against sodium hydroxide and other hazardous substances. This includes smart fabrics that can detect and alert users to potential exposure.

Automated Handling Systems: To reduce the need for direct human contact with sodium hydroxide, automated handling systems are being introduced. These systems use robotics and advanced sensors to handle, transfer, and store sodium hydroxide with precision, minimizing the risk of accidents and exposure.

Smart Monitoring and Control: Cutting-edge monitoring technologies, such as real-time sensors and advanced analytics, are being employed to track and control sodium hydroxide concentrations and exposure levels. These systems can provide early warnings of potential hazards and help optimize safety protocols.

Green Chemistry Approaches: The concept of green chemistry, which focuses on minimizing environmental impact and promoting sustainability, is influencing the way sodium hydroxide is used and handled. Researchers are exploring alternative processes and formulations that reduce the need for sodium hydroxide or allow for safer disposal methods.

Education and Training Technologies: Virtual reality (VR) and augmented reality (AR) are being utilized to create immersive training experiences that simulate various scenarios involving sodium hydroxide. These technologies provide a safe and engaging way to educate workers about proper handling procedures and emergency response protocols.

Conclusion: A Culture of Safety

In the world of sodium hydroxide handling, safety is not just a set of guidelines to follow but a culture to embrace. By implementing robust safety protocols, staying informed about emerging trends, and fostering a culture of awareness and respect for potential hazards, we can ensure that sodium hydroxide remains a valuable asset without compromising the well-being of individuals or the environment.

As we continue to advance our understanding and application of sodium hydroxide, let’s prioritize safety at every step, setting a benchmark for responsible chemical management in various industries.

Remember, when it comes to sodium hydroxide safety, knowledge is power, and together, we can create a safer, more sustainable future.