Understanding Steel's Modulus of Elasticity

Steel, a ubiquitous material in construction and engineering, exhibits remarkable strength and versatility. At the heart of its mechanical behavior lies the modulus of elasticity, a fundamental property that governs how steel responds to external forces. In this exploration, we delve into the intricacies of steel’s modulus of elasticity, examining its definition, significance, and practical implications.

The modulus of elasticity, often denoted as E or Young’s modulus, represents a material’s resistance to elastic deformation when subjected to an applied force. In the context of steel, this property quantifies how much the metal will stretch or compress under a given stress. It is a critical parameter that influences the design and performance of structures, machinery, and various steel-based components.

The modulus of elasticity serves as a cornerstone in structural engineering, providing engineers with a vital tool to predict and manage the behavior of steel elements under load.

Understanding this property is essential for ensuring the safety and integrity of steel structures, from towering skyscrapers to intricate mechanical systems.

Historical Evolution of Steel’s Modulus of Elasticity

The concept of modulus of elasticity has a rich historical context, dating back to the early days of materials science. While the idea of material stiffness has been recognized for centuries, the precise measurement and understanding of Young’s modulus evolved alongside the development of engineering and scientific methodologies.

In the 19th century, pioneering researchers like Thomas Young and Augustin-Louis Cauchy laid the groundwork for our modern understanding of elasticity. Their experiments and theories formed the basis for calculating and predicting material behavior under stress, leading to the formulation of the modulus of elasticity as a fundamental material property.

Theoretical Breakdown

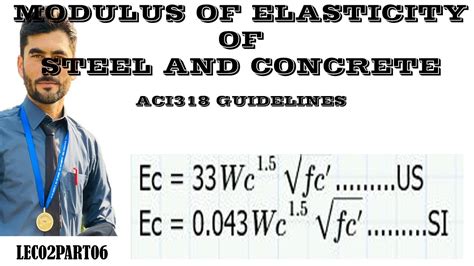

The modulus of elasticity for steel is derived from fundamental principles of physics and mechanics. It is defined as the ratio of stress to strain within the elastic region of a material’s stress-strain curve. This elastic region represents the portion of the curve where the material returns to its original shape after the removal of the applied force.

Mathematically, the modulus of elasticity (E) is expressed as:

E = σ / ε

where σ represents stress (force per unit area) and ε represents strain (change in length per original length). This equation encapsulates the fundamental relationship between the applied force and the resulting deformation in steel.

Practical Implications

The modulus of elasticity of steel has far-reaching implications across various engineering disciplines. Here are some key areas where this property plays a pivotal role:

Structural Design: Engineers rely on steel’s modulus of elasticity to calculate the deformation and stress distribution in structures like bridges, buildings, and towers. This information is critical for ensuring the structural integrity and safety of these edifices.

Machinery and Equipment: In the design of machinery and industrial equipment, the modulus of elasticity helps engineers predict how steel components will behave under dynamic loads, ensuring efficient operation and preventing catastrophic failures.

Material Selection: When choosing steel for a particular application, the modulus of elasticity is a key factor. Different steel grades offer varying moduli, influencing their suitability for specific tasks.

Comparative Analysis

Steel’s modulus of elasticity is often compared to that of other materials to assess its relative performance. Here’s a brief comparison:

| Material | Modulus of Elasticity (GPa) |

|---|---|

| Steel (average) | 200 |

| Aluminum | 70 |

| Concrete | 30 |

| Wood (soft) | 10 |

| Rubber | 0.1 |

This table highlights the significant difference in elastic behavior between steel and other common materials. Steel’s high modulus indicates its exceptional stiffness and resistance to deformation, making it a preferred choice for applications requiring structural strength and rigidity.

Case Study: High-Rise Building Construction

To illustrate the practical application of steel’s modulus of elasticity, let’s consider the construction of a high-rise building. In this scenario, engineers must carefully consider the behavior of steel beams and columns to ensure the building’s stability and safety.

The modulus of elasticity helps determine the amount of deflection that these structural elements will experience under the building’s weight and wind loads. By accurately predicting these deformations, engineers can design the building to withstand the expected forces without compromising its structural integrity.

Future Trends and Emerging Technologies

As engineering and construction continue to evolve, new technologies and materials are emerging that challenge traditional steel’s dominance. However, steel remains a cornerstone material due to its unique combination of strength, durability, and versatility.

Researchers are exploring advanced steel alloys and manufacturing techniques to enhance steel’s modulus of elasticity and other mechanical properties. These innovations aim to improve the performance of steel in demanding applications, such as aerospace and high-speed transportation systems.

Conclusion

In conclusion, the modulus of elasticity is a critical property of steel that underpins its widespread use in engineering and construction. By understanding this fundamental concept, engineers and designers can harness the full potential of steel, ensuring the safety, efficiency, and longevity of structures and systems.

As we continue to push the boundaries of what steel can achieve, the study and optimization of its modulus of elasticity remain essential in unlocking new possibilities and shaping our built environment.

The modulus of elasticity is a vital parameter that governs steel's behavior under stress, playing a pivotal role in ensuring the safety and performance of steel-based structures and components.

What is the average modulus of elasticity for steel?

+The average modulus of elasticity for steel is approximately 200 GPa (gigapascals), although it can vary depending on the specific steel grade and alloy composition.

<div class="faq-item">

<div class="faq-question">

<h3>How does the modulus of elasticity affect steel's behavior in structures?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>A higher modulus of elasticity indicates greater stiffness and resistance to deformation. This property is crucial in structural design, as it helps predict how steel elements will behave under load, ensuring stability and safety.</p>

</div>

</div>

<div class="faq-item">

<div class="faq-question">

<h3>Can the modulus of elasticity be modified for steel alloys?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>Yes, the modulus of elasticity can be altered by adjusting the alloy composition and manufacturing processes. Researchers are actively exploring ways to enhance steel's mechanical properties, including its modulus of elasticity, to meet the demands of advanced engineering applications.</p>

</div>

</div>

<div class="faq-item">

<div class="faq-question">

<h3>What are the practical applications of understanding steel's modulus of elasticity?</h3>

<span class="faq-toggle">+</span>

</div>

<div class="faq-answer">

<p>Understanding steel's modulus of elasticity is crucial for structural design, machinery construction, and material selection. It allows engineers to predict and manage steel's behavior under various loads, ensuring the safety and efficiency of structures and equipment.</p>

</div>

</div>

</div>