Build Your Own Blast Furnace: A Step-by-Step Guide

A Journey into Ancient Metallurgy

Creating a blast furnace from scratch is an ambitious endeavor, one that requires a deep understanding of metallurgical principles and a fair bit of hands-on craftsmanship. In this guide, we’ll walk you through the entire process, from gathering the raw materials to producing your first batch of molten metal.

The blast furnace is an iconic symbol of the Industrial Revolution, a testament to humanity’s ability to transform raw earth into powerful tools and materials. Today, we’ll delve into the heart of this ancient technology, exploring its inner workings and providing you with the knowledge to construct your own.

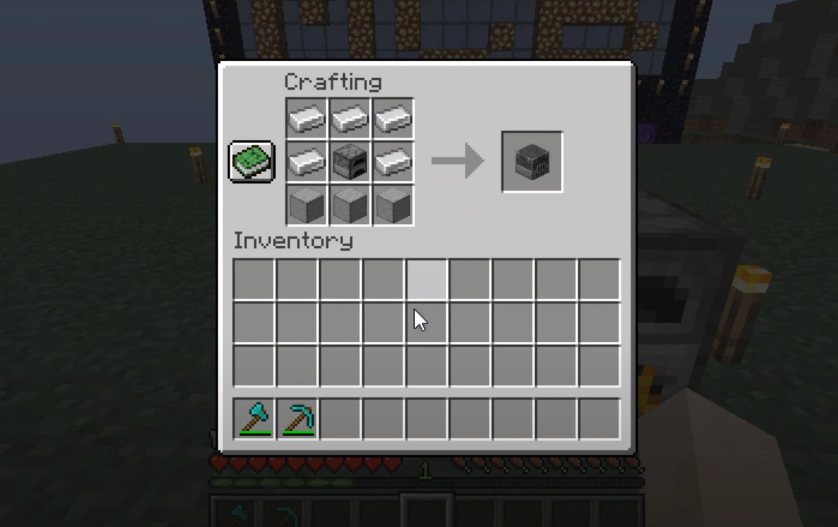

Step 1: Understanding the Blast Furnace

Before we begin construction, it’s essential to grasp the fundamental principles behind the blast furnace. This towering structure is designed to reduce iron ore into pig iron, a crucial step in the steelmaking process.

At its core, the blast furnace operates on a simple yet powerful concept: by forcing a blast of hot air through a charged mixture of iron ore, coke (a type of carbon), and limestone, we can create a chemical reaction that separates the iron from its ore. This process, known as smelting, has been used for millennia to produce iron and steel.

The Chemistry Behind the Furnace

In a blast furnace, the key chemical reaction is the reduction of iron oxide (Fe2O3) to iron (Fe). This reduction is facilitated by the coke, which provides the necessary carbon to react with the oxygen in the iron oxide:

\[ \text{Fe}_2\text{O}_3 + 3\text{C} \rightarrow 2\text{Fe} + 3\text{CO} \]

Additionally, the limestone (CaCO3) plays a crucial role in capturing impurities, forming slag:

\[ \text{CaCO}_3 \rightarrow \text{CaO} + \text{CO}_2 \]

\[ \text{CaO} + \text{Si} \rightarrow \text{CaSiO}_3 \]

This slag floats on top of the molten iron, allowing for its easy removal.

Step 2: Gathering the Raw Materials

The success of your blast furnace project hinges on obtaining the right raw materials. Here’s a comprehensive list of what you’ll need:

- Iron Ore: The primary feedstock, typically hematite (Fe2O3) or magnetite (Fe3O4). Ensure you have a consistent source of high-quality ore.

- Coke: This is produced by heating coal to high temperatures in the absence of air, driving off impurities. It’s crucial for providing the necessary carbon for the reduction reaction.

- Limestone: As mentioned, limestone (CaCO3) is essential for capturing impurities. It should be finely crushed to ensure even distribution.

- Refractory Materials: You’ll need materials like clay, sand, and firebricks to construct the furnace’s inner lining. These materials must withstand extreme heat.

- Fuel: Depending on your design, you might need additional fuel sources, such as charcoal or wood, to maintain the furnace’s temperature.

- Air Supply: A steady supply of air, often provided by a bellows or a mechanical blower, is crucial for the combustion process.

- Tools and Equipment: Gather a range of tools, including shovels, rakes, and specialized refractory tools for lining the furnace.

Step 3: Designing Your Blast Furnace

The design of your blast furnace is a critical aspect, as it will determine its efficiency and longevity. Here are some key considerations:

- Size and Shape: Blast furnaces can vary in size, from small, experimental designs to massive industrial structures. Consider the scale of your project and the amount of metal you aim to produce.

- Tapping System: Decide on the method for tapping the molten iron. This can be done through a taphole at the bottom of the furnace or via a spout system.

- Air Supply: Determine how you’ll introduce air into the furnace. A bellows system can be effective for smaller furnaces, while larger ones might require mechanical blowers.

- Charging Mechanism: Consider how you’ll charge the furnace with the raw materials. A simple chute system or a more intricate charging mechanism can be designed.

- Safety Features: Don’t forget about safety! Implement systems to monitor and control temperature, and ensure proper ventilation to avoid dangerous gases.

Step 4: Constructing the Furnace

Now comes the hands-on part—building your blast furnace. This process can be complex and requires careful attention to detail. Here’s a general overview:

- Foundation: Start by constructing a sturdy foundation for your furnace. This should be made of refractory materials to withstand the intense heat.

- Lining the Furnace: Using your refractory materials, carefully line the interior of the furnace. Ensure a smooth and even lining, as any imperfections can affect the efficiency of the furnace.

- Air Supply System: Install your chosen air supply system, whether it’s a bellows or a blower. Ensure it’s capable of providing a steady, controlled airflow.

- Charging Mechanism: Build the mechanism for charging the furnace with raw materials. This could be a simple chute or a more intricate system with gates and controls.

- Tapping System: Implement the tapping system, ensuring it’s easy to operate and capable of safely extracting the molten iron.

- Safety Precautions: Install temperature sensors, gas detectors, and ventilation systems to ensure the safety of operators and nearby personnel.

Step 5: Charging and Operating the Furnace

With your blast furnace constructed, it’s time to bring it to life. Here’s a step-by-step guide to charging and operating your furnace:

- Preheating: Start by preheating the furnace to ensure the lining is at the correct temperature. This can be done by burning charcoal or wood inside the furnace.

- Charging the Furnace: Carefully introduce the iron ore, coke, and limestone into the furnace through your charging mechanism. Ensure an even distribution of materials.

- Lighting the Fire: Ignite the fuel at the base of the furnace, and gradually increase the airflow to create a steady, intense flame.

- Monitoring the Process: Keep a close eye on the temperature and the progress of the smelting process. Adjust the airflow as needed to maintain optimal conditions.

- Tapping the Iron: Once the iron has been reduced and is in its molten form, carefully tap it into a suitable container, such as a refractory mold or a crucible.

- Cooling and Maintenance: After tapping, allow the furnace to cool down gradually. Regular maintenance, such as relining and repairing any cracks, is essential to keep your furnace in top condition.

Step 6: Refining and Casting the Metal

The molten iron produced by your blast furnace is known as pig iron, which is relatively impure and not suitable for most applications. To transform it into usable steel, further refining processes are required:

- Refining: Pig iron can be refined through processes like basic oxygen steelmaking or electric arc furnace methods. These processes remove impurities and adjust the carbon content to produce steel of various grades.

- Casting: Once refined, the steel can be cast into various shapes and forms, such as ingots or billets, using specialized molds.

Conclusion: A Journey into Metallurgical Mastery

Constructing a blast furnace is a complex and rewarding endeavor, one that offers a deep insight into the ancient art of metallurgy. By following this guide, you’ve embarked on a journey that connects you to the pioneers of the Industrial Revolution and the countless generations who have relied on iron and steel to shape our world.

As you continue your metallurgical adventures, remember that practice and experimentation are key. Each blast furnace is a unique creation, and with time and experience, you’ll develop the skills to refine your designs and produce even better results.

So, keep the fire burning, and let your blast furnace be a testament to your craftsmanship and a gateway to the fascinating world of metallurgy!