Master the Art: Measuring Diameters Accurately

The precision with which diameters are measured is a crucial aspect of numerous industries, from manufacturing and engineering to scientific research and quality control. Accurate diameter measurement is the cornerstone of ensuring product quality, optimizing processes, and meeting stringent industry standards. This article will delve into the art of measuring diameters accurately, exploring the tools, techniques, and best practices that professionals employ to achieve unparalleled precision.

The Significance of Diameter Measurement

Imagine a scenario where a manufacturing company produces precision mechanical components for aerospace applications. The accuracy of the diameters on these components is not just a matter of quality but a matter of safety. A slight deviation in the diameter of a critical part could lead to catastrophic failures in flight, underscoring the gravity of precise diameter measurement.

Beyond safety concerns, accurate diameter measurement is essential for maintaining product consistency, ensuring customer satisfaction, and reducing waste. In industries where tolerances are measured in microns, the slightest measurement error can lead to significant losses in both time and resources.

Choosing the Right Tools for the Task

Selecting the appropriate tools for diameter measurement is the first critical step in the process. Here’s a breakdown of some of the most commonly used instruments and their applications:

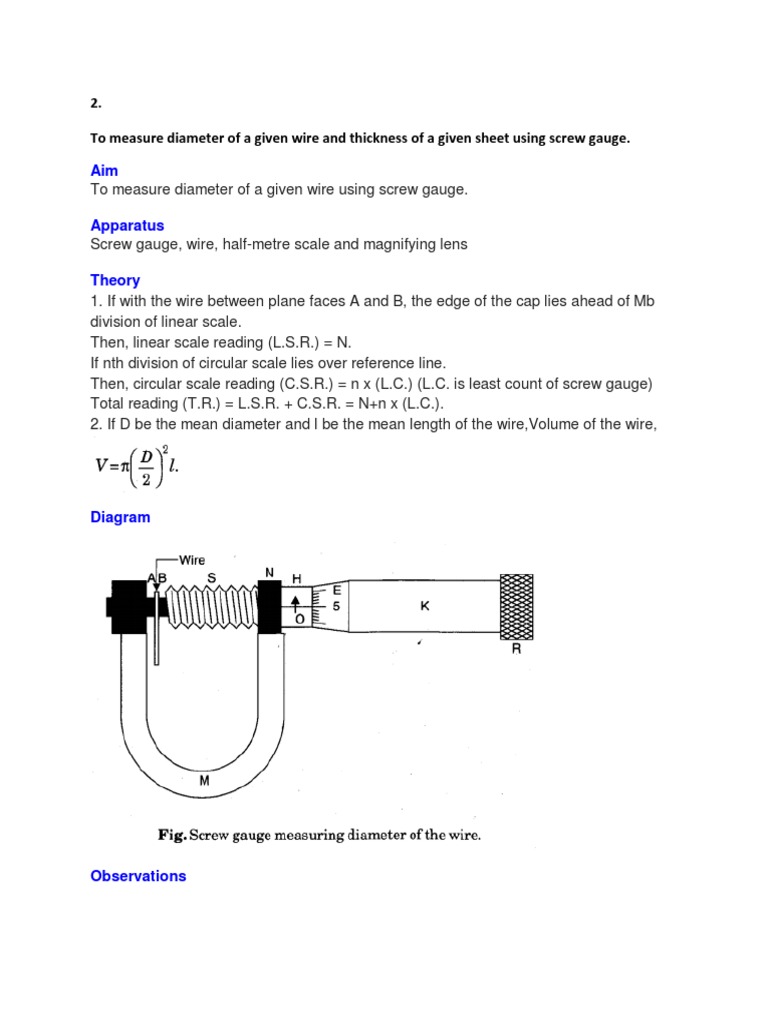

Micrometers: These precision instruments are widely used for measuring external diameters. Micrometers offer high accuracy and are available in various types, including digital and mechanical versions, each suited to different applications and levels of precision.

Calipers: Calipers, whether digital or traditional, are versatile tools that can measure both external and internal diameters. They are particularly useful for quick, initial measurements and are often the first tool of choice for many professionals.

Dial Indicators: Dial indicators are indispensable for measuring small diameter variations. By attaching them to a precision stand, professionals can accurately measure the diameter of a part by taking multiple readings at different points.

Coordinate Measuring Machines (CMMs): CMMs are advanced, computer-controlled machines capable of measuring complex geometries, including diameters, with unparalleled accuracy. While CMMs are more costly and complex to operate, they are essential for high-precision applications and batch production.

Laser Scanners: Laser scanners provide a non-contact method of diameter measurement, making them ideal for delicate or heat-sensitive parts. These scanners can rapidly capture thousands of data points, providing highly accurate diameter measurements.

Techniques for Accurate Diameter Measurement

Mastering the art of diameter measurement involves more than just selecting the right tools. Here are some key techniques that professionals employ to ensure the utmost accuracy:

Zeroing and Calibration: Before any measurement, it’s crucial to zero and calibrate the instrument. This process ensures that the tool starts from a known reference point, minimizing potential errors.

Multiple Readings: Taking multiple measurements at different points on the diameter is standard practice. By averaging these readings, professionals can account for potential irregularities in the part and achieve a more accurate result.

Environmental Control: Environmental factors such as temperature and humidity can influence measurement accuracy. Professionals often work in controlled environments or employ temperature-compensated instruments to mitigate these effects.

Part Preparation: The condition of the part being measured is critical. It should be clean, free from debris, and properly aligned to ensure accurate measurements. In some cases, parts may require special preparation, such as being coated with a reflective material for laser scanning.

Statistical Analysis: In high-precision applications, statistical analysis techniques like gauge R&R (repeatability and reproducibility) studies are used to assess the reliability of measurement systems. These studies help identify sources of variation and ensure consistent, accurate measurements.

Best Practices for Consistent Results

Achieving consistent results in diameter measurement requires adherence to a set of best practices. Here are some key recommendations:

Operator Training: Proper training is essential for operators to understand the principles of diameter measurement, the correct use of instruments, and the interpretation of results. Well-trained operators can identify potential issues and make informed decisions.

Standard Operating Procedures (SOPs): Developing and following SOPs ensures that measurement processes are consistent across different operators and shifts. SOPs should cover instrument calibration, measurement techniques, and data recording procedures.

Regular Instrument Maintenance: Instruments should be regularly calibrated and maintained to ensure their accuracy. Calibration should be performed by qualified personnel using traceable standards.

Data Management: Effective data management is crucial for tracking measurement results and identifying trends. Advanced data analysis tools can help identify potential issues and improve measurement processes over time.

Continuous Improvement: The field of diameter measurement is constantly evolving. Staying updated with the latest techniques, instruments, and industry standards is essential for maintaining a competitive edge and ensuring the highest level of accuracy.

Advanced Techniques for Specialized Applications

In certain specialized industries, such as aerospace and medical device manufacturing, the need for extremely precise diameter measurements is even more critical. Here are some advanced techniques employed in these sectors:

Interferometry: Interferometry is a highly precise method used to measure diameters at the sub-micron level. This technique employs the interference of light waves to detect even the slightest variations in diameter.

Non-Contact Optical Sensors: Non-contact optical sensors, such as laser displacement sensors, offer an alternative to traditional contact methods. These sensors can measure diameters without physically touching the part, reducing the risk of damage to delicate components.

Machine Vision Systems: Machine vision systems use cameras and advanced image processing techniques to measure diameters automatically. These systems are particularly useful in high-volume production environments, where speed and accuracy are paramount.

The Future of Diameter Measurement

As technology continues to advance, the future of diameter measurement holds exciting possibilities. Here’s a glimpse into some emerging trends:

Artificial Intelligence (AI): AI-powered systems are being developed to automate diameter measurement processes. These systems can analyze large datasets, identify patterns, and make real-time adjustments to measurement techniques, improving accuracy and efficiency.

Portable Measurement Devices: The development of portable, handheld devices that can measure diameters accurately is on the rise. These devices offer the flexibility to measure parts on the production floor or even in the field, reducing the need for specialized measurement labs.

Cloud-Based Data Management: Cloud-based platforms are enabling the secure storage and sharing of measurement data across different locations and teams. This facilitates real-time collaboration and data analysis, enhancing efficiency and decision-making.

Conclusion: The Art of Precision

Measuring diameters accurately is a blend of art and science, requiring a deep understanding of tools, techniques, and best practices. Whether it’s ensuring the safety of aerospace components or optimizing production processes, accurate diameter measurement is a critical skill that underpins numerous industries.

By embracing the latest advancements, adhering to best practices, and continuously improving their skills, professionals can achieve unparalleled precision in diameter measurement, driving innovation and excellence in their respective fields.

What are some common challenges faced in diameter measurement, and how can they be overcome?

+Common challenges in diameter measurement include environmental factors, operator error, and instrument limitations. To overcome these challenges, professionals employ techniques such as environmental control, rigorous operator training, and the use of advanced instruments like CMMs and laser scanners.

How can I ensure consistent results when measuring diameters in a production environment?

+Consistency in diameter measurement can be achieved through the implementation of Standard Operating Procedures (SOPs), regular instrument calibration, and operator training. Additionally, advanced data analysis tools can help identify measurement trends and potential issues, ensuring consistent results over time.

What are the key considerations when selecting the right instrument for diameter measurement?

+The choice of instrument depends on factors such as the level of precision required, the type of part being measured (external or internal diameter), and the environmental conditions. Professionals should consider the instrument’s accuracy, ease of use, and suitability for the specific application.

How do I ensure the accuracy of my measurement data over time?

+Maintaining accuracy over time involves regular instrument calibration, following SOPs, and conducting gauge R&R studies to assess the reliability of measurement systems. Additionally, investing in advanced data management systems can help track measurement results, identify trends, and improve measurement processes.