Understanding Face-Centered Cubic Structures

The face-centered cubic (fcc) structure is a fundamental concept in materials science, with profound implications for various industries. This crystal structure, also known as cubic close-packed (ccp), forms the backbone of numerous metallic alloys and compounds, influencing their mechanical, electrical, and thermal properties. Understanding the intricacies of this structure is pivotal for engineers, scientists, and material designers seeking to optimize material performance.

At its core, the fcc structure is characterized by a highly efficient packing arrangement of atoms or ions. This arrangement maximizes the utilization of space, resulting in a dense and stable crystal lattice. Each atom in the lattice is surrounded by twelve nearest neighbors, six located on the cube faces and three on the body diagonals, forming an intricate network. This unique arrangement confers remarkable strength and unique physical properties to materials exhibiting this structure.

In this comprehensive exploration, we will delve into the details of the face-centered cubic structure, examining its formation, characteristics, and applications. By unraveling the complexities of this crystal lattice, we can appreciate its critical role in shaping the properties of many essential materials. This journey will not only enhance our understanding of materials science but also empower us to make informed decisions in material selection and design.

The Formation of Face-Centered Cubic Structures

The formation of fcc structures involves a meticulous arrangement of atoms or ions, governed by the principles of atomic packing. In this process, atoms are positioned in a manner that minimizes the overall energy of the system while maximizing the stability of the crystal lattice. The resulting fcc structure is one of the most tightly packed and energetically favorable arrangements possible.

Imagine the formation process as a delicate dance of atoms, each seeking the optimal position to balance attractive and repulsive forces. In the fcc lattice, this equilibrium is achieved by placing atoms at the centers of cube faces, creating a highly symmetrical and ordered arrangement. This symmetrical arrangement is not only aesthetically pleasing but also crucial for the exceptional properties exhibited by fcc materials.

Key Characteristics of Face-Centered Cubic Structures

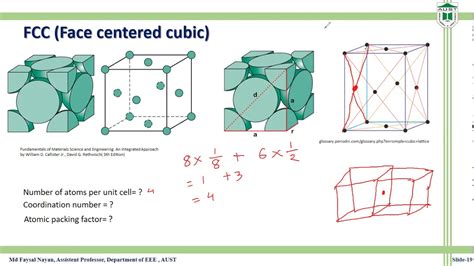

The fcc structure boasts several distinctive characteristics that set it apart from other crystal lattices:

High Packing Efficiency: With a packing efficiency of approximately 74%, the fcc structure is one of the most densely packed crystal lattices. This high packing efficiency contributes to the strength and stability of materials with this structure.

Coordination Number: In an fcc lattice, each atom is surrounded by twelve nearest neighbors, providing a highly connected and stable network. This coordination number of twelve is a unique feature of the fcc structure, influencing its mechanical and electrical properties.

Symmetry: The fcc structure exhibits a high degree of symmetry, with identical atoms or ions occupying equivalent lattice positions. This symmetry not only enhances the stability of the crystal lattice but also contributes to the isotropic behavior of fcc materials, where properties remain consistent in all directions.

Slip Systems: Fcc structures possess an extensive network of slip systems, which are planes of atoms that can easily glide over each other. This characteristic is crucial for the plasticity and ductility of fcc materials, allowing them to deform under stress without fracturing.

The combination of these characteristics makes fcc structures highly desirable for various applications, particularly in engineering and metallurgy.

Real-World Applications of Face-Centered Cubic Structures

The face-centered cubic structure finds widespread application across diverse industries, underscoring its significance in materials science. Here are some notable examples:

Metallic Alloys: Many common metallic alloys, such as aluminum alloys, brass, and certain stainless steels, exhibit the fcc structure. These alloys are valued for their excellent strength-to-weight ratio, corrosion resistance, and ease of fabrication, making them essential in aerospace, automotive, and construction industries.

Semiconductors: The fcc structure is prevalent in semiconductor materials, such as silicon and germanium. These materials are crucial for the fabrication of electronic devices, including transistors, integrated circuits, and solar cells. The unique properties of fcc semiconductors enable the precise control of electrical conductivity, facilitating the development of advanced electronic technologies.

Pharmaceuticals: In the pharmaceutical industry, face-centered cubic structures are utilized in the formulation of various drugs. The fcc structure’s high packing efficiency and stability make it an ideal candidate for drug delivery systems, ensuring the effective and controlled release of medications.

Catalysts: Fcc-structured materials are also employed as catalysts in chemical reactions. Their high surface area and unique electronic properties enhance catalytic activity, making them indispensable in various industrial processes, including petroleum refining and pollution control.

These real-world applications demonstrate the versatility and importance of the face-centered cubic structure. By harnessing the unique properties of this crystal lattice, scientists and engineers can develop innovative materials and technologies to meet the challenges of modern society.

Challenges and Opportunities in Face-Centered Cubic Materials

While the face-centered cubic structure offers numerous advantages, it also presents certain challenges that researchers and engineers must navigate:

Strength-Ductility Trade-off: Fcc materials often exhibit a trade-off between strength and ductility. While they are known for their high strength, their ductility can be limited, making them susceptible to brittle failure under certain conditions. Balancing these properties is a key challenge in material design.

Corrosion Resistance: Despite their excellent mechanical properties, some fcc alloys are prone to corrosion, particularly in aggressive environments. Developing corrosion-resistant coatings and alloys is an ongoing area of research to enhance the durability and longevity of these materials.

Phase Transformations: Fcc structures can undergo phase transformations under specific conditions, such as changes in temperature or pressure. Understanding and controlling these transformations is crucial to maintain the desired material properties and performance.

However, these challenges also present opportunities for innovation. By overcoming these limitations, researchers can unlock new possibilities for material design, leading to the development of advanced alloys and compounds with enhanced performance characteristics.

The Future of Face-Centered Cubic Materials

The face-centered cubic structure continues to be a subject of intense research and development, with promising prospects for the future. As our understanding of materials science deepens, we can anticipate the following advancements:

Enhanced Material Properties: Through advanced alloying and processing techniques, researchers can fine-tune the properties of fcc materials, enhancing their strength, ductility, and corrosion resistance. This will lead to the development of high-performance alloys for demanding applications in aerospace, energy, and transportation industries.

Smart Materials: By incorporating functional additives and nanostructures into fcc materials, scientists can create smart materials with responsive and adaptable properties. These materials can dynamically adjust their characteristics in response to external stimuli, offering unprecedented control and functionality.

Sustainable Materials: The sustainable and environmentally friendly production of fcc materials is an emerging focus area. Researchers are exploring green synthesis methods and recycling technologies to reduce the environmental impact of these materials, ensuring their long-term viability and sustainability.

The future of face-centered cubic materials holds immense potential, with new applications and innovations on the horizon. By continuing to explore and harness the unique properties of this crystal structure, we can unlock exciting possibilities for technology and industry.

What is the significance of the face-centered cubic structure in materials science?

+The face-centered cubic structure is significant in materials science due to its dense and stable crystal lattice, which imparts unique mechanical, electrical, and thermal properties to materials. Its high packing efficiency, coordination number, and symmetry make it a desirable structure for various applications, from metallic alloys to semiconductors and pharmaceuticals.

How does the fcc structure compare to other crystal lattices in terms of packing efficiency and stability?

+The fcc structure is highly efficient in terms of packing, with a packing efficiency of approximately 74%. This makes it one of the most densely packed crystal lattices, rivaling the hexagonal close-packed (hcp) structure. The fcc structure's stability is attributed to its symmetrical arrangement and coordination number of twelve, which contributes to the strength and stability of materials.

What are the key advantages of using face-centered cubic materials in engineering and metallurgy?

+Face-centered cubic materials offer several advantages, including excellent strength, a high strength-to-weight ratio, and good ductility. They are also known for their ease of fabrication and corrosion resistance, making them ideal for various engineering applications, particularly in industries such as aerospace, automotive, and construction.

Can you provide examples of real-world applications where face-centered cubic structures are essential?

+Face-centered cubic structures are critical in many real-world applications. For instance, aluminum alloys with the fcc structure are widely used in the aerospace industry due to their lightweight and high strength. In the semiconductor industry, fcc-structured materials like silicon and germanium are essential for fabricating electronic devices. Additionally, fcc-structured catalysts play a vital role in various chemical processes, such as petroleum refining.

What are the challenges and opportunities associated with face-centered cubic materials?

+Face-centered cubic materials present challenges such as the strength-ductility trade-off and corrosion susceptibility. However, these challenges also offer opportunities for innovation. Researchers can explore advanced alloying techniques and coatings to enhance the properties of fcc materials, leading to the development of high-performance alloys with improved strength, ductility, and corrosion resistance.

In conclusion, the face-centered cubic structure is a cornerstone of materials science, with its dense and stable crystal lattice underpinning the properties of numerous materials. Its unique characteristics, from high packing efficiency to extensive slip systems, make it a preferred structure for applications ranging from metallic alloys to semiconductors and pharmaceuticals. As research continues to unlock the potential of fcc materials, we can anticipate exciting advancements in material design, leading to more efficient, sustainable, and innovative technologies.