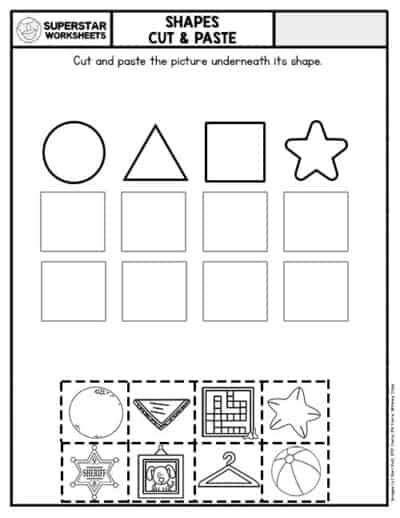

The Ultimate Guide to Shape Cutting and Pasting

Welcome to the world of shape cutting and pasting, an essential technique in various creative fields, from graphic design and digital art to crafting and even industrial manufacturing. This guide aims to provide an in-depth exploration of shape cutting and pasting, its applications, and its impact on modern industries. We'll delve into the processes, tools, and strategies used by professionals, offering a comprehensive resource for anyone interested in mastering this art.

Understanding the Fundamentals of Shape Cutting

Shape cutting, a process that involves precise cutting of materials to create desired shapes, is an art form in itself. It’s a vital skill for designers, artists, and makers, allowing them to bring their creative visions to life. This section will delve into the core principles and techniques of shape cutting, exploring the various methods and tools used in the industry.

Traditional Shape Cutting Methods

Historically, shape cutting was a labor-intensive process. Craftsmen used hand tools like knives, saws, and scissors to carefully cut materials such as wood, metal, and paper. These traditional methods required skill, patience, and an eye for precision. While they are still used in certain contexts, modern advancements have revolutionized the shape cutting process.

For example, in the crafting world, quilters often use rotary cutters and self-healing mats to precisely cut fabric pieces for their intricate designs. Similarly, sign makers might use hand-held jigsaws to cut intricate shapes out of wood for signage.

Introduction to Digital Shape Cutting

The advent of digital technology has transformed shape cutting. With computer-controlled cutting machines, designers can now input digital designs and have them precisely cut with minimal manual intervention. This has led to a significant increase in speed, accuracy, and complexity of shapes that can be achieved.

One popular digital shape cutting machine is the Cricut Maker, which uses a rotary blade to cut a wide variety of materials, from fabric and paper to leather and balsa wood. The Maker connects to a computer or mobile device, allowing users to design shapes digitally and then cut them with incredible precision.

| Machine | Materials Cut | Max Cutting Size |

|---|---|---|

| Cricut Maker | 100+ materials | 12" x 24" |

| Silhouette Cameo 4 | 3mm thick materials | 12" x 10" |

| Brother ScanNCut DX | Fabric, paper, vinyl | 12" x 12" |

Digital shape cutting has opened up new possibilities for designers, enabling them to create complex, detailed shapes that were previously difficult or time-consuming to achieve by hand.

Advanced Techniques in Shape Cutting

In certain industries, shape cutting takes on an even more sophisticated form. For instance, in the aerospace industry, waterjet cutting is used to cut precise shapes from materials like metal and stone. This method uses a high-pressure stream of water, often mixed with an abrasive substance, to erode the material along a programmed path.

Another advanced technique is laser cutting, which utilizes a focused laser beam to cut materials. This method is particularly useful for cutting intricate shapes and patterns, and it's commonly used in the fashion industry for cutting fabric with precision and speed.

Mastering the Art of Shape Pasting

Once shapes are cut, the next step is often to assemble or paste them together to create a final design or product. This section will explore the techniques and considerations involved in shape pasting, ensuring that your creations are not only aesthetically pleasing but also structurally sound.

Choosing the Right Adhesive

The choice of adhesive is critical in shape pasting. Different materials require different adhesives for optimal bonding. For instance, when pasting paper shapes, a simple glue stick or white glue may suffice, while fabric shapes might require a stronger, fabric-specific adhesive.

For more complex projects, especially those involving mixed media, choosing the right adhesive can be a challenge. Consider the following when selecting an adhesive:

- Material Compatibility: Ensure the adhesive is suitable for both the base material and the material being attached.

- Drying Time: Choose an adhesive with a drying time that aligns with your project's timeline.

- Strength: Consider the level of strength required for your project. Will the pieces be subjected to stress or movement?

- Appearance: Some adhesives can leave residue or discolor certain materials. Choose one that won't detract from your design.

Techniques for Flawless Shape Pasting

Mastering the art of shape pasting requires practice and attention to detail. Here are some techniques to ensure your shapes align perfectly and adhere securely:

- Use Guides: When pasting multiple shapes, use guides or templates to ensure accurate alignment. This can be as simple as using a ruler and pencil to mark placement.

- Apply Adhesive Sparingly: Too much adhesive can cause overflow and may weaken the bond. Apply adhesive sparingly, ensuring good contact between the shapes.

- Clamping or Weighing: Depending on the project, you may need to clamp or weigh down the shapes while the adhesive sets to prevent movement.

- Practice on Scraps: Before applying adhesive to your final project, practice on scrap materials to perfect your technique.

Advanced Shape Pasting Techniques

For complex projects or when working with intricate shapes, advanced techniques can elevate your shape pasting skills. These might include:

- Layering: Build up your design by layering shapes of different sizes and materials. This can add depth and interest to your creation.

- Incorporating Mixed Media: Combine different materials like paper, fabric, wood, or metal to create unique, textured designs.

- Incorporating 3D Elements: Add dimension to your designs by incorporating shapes that stand off the page or surface. This could be as simple as using foam adhesive to raise certain elements.

Applications of Shape Cutting and Pasting

Shape cutting and pasting techniques find applications across a broad spectrum of industries and artistic pursuits. This section will explore some of these diverse applications, showcasing the versatility and impact of these skills.

Graphic Design and Digital Art

In the digital realm, shape cutting and pasting take on a new dimension. Graphic designers often use shape cutting tools to create digital stencils, which can then be used to add texture, depth, and visual interest to their designs. These shapes can be combined, overlapped, and manipulated digitally to create unique compositions.

Digital artists, on the other hand, might use shape cutting to create intricate, layered designs that can be printed or used as digital assets. The ability to precisely cut and paste shapes allows for a high level of control and creativity in digital art.

Crafting and DIY

The crafting world is a haven for shape cutting and pasting enthusiasts. Whether it’s scrapbooking, card making, or quilting, these techniques are fundamental to creating unique, personalized projects.

For example, scrapbookers might use shape cutting to create custom die-cuts for their pages, while card makers use intricate shapes to add interest and dimension to their designs. Quilters often use shape cutting to create complex fabric patterns and appliques.

Industrial and Manufacturing Applications

Shape cutting and pasting are not limited to the creative arts. In the industrial sector, these techniques are used for prototyping, product development, and even large-scale manufacturing.

For instance, rapid prototyping often involves shape cutting to create physical models of products, allowing designers and engineers to test and refine their designs before full-scale production. In manufacturing, shape cutting is used to create custom parts and components for a wide range of industries, from automotive to aerospace.

The Future of Shape Cutting and Pasting

As technology continues to advance, the future of shape cutting and pasting looks bright. We can expect to see further innovations in digital cutting technology, with machines becoming more versatile, precise, and user-friendly.

The integration of artificial intelligence and machine learning could also revolutionize the field. These technologies could enable machines to learn and adapt to different materials and designs, making the cutting process even more efficient and accurate.

Additionally, the rise of 3D printing and additive manufacturing could further enhance the capabilities of shape cutting and pasting, allowing for the creation of complex, multi-dimensional designs.

Conclusion

Shape cutting and pasting is a versatile skill with applications across various industries and artistic pursuits. Whether you’re a designer, artist, crafter, or maker, mastering these techniques can open up a world of creative possibilities. With the right tools, materials, and knowledge, you can bring your visions to life, crafting unique and beautiful designs.

Remember, practice makes perfect. Experiment with different materials, techniques, and tools to find what works best for your projects. And don't be afraid to push the boundaries, as innovation often stems from creative exploration.

FAQ

What is the best digital shape cutting machine for beginners?

+

For beginners, the Cricut Explore Air 2 is a great option. It’s user-friendly, versatile, and offers a wide range of materials to cut. It’s also more affordable than some of the more advanced machines, making it a great entry point into digital shape cutting.

Can I use digital shape cutting machines for fabric?

+

Absolutely! Many digital shape cutting machines, like the Brother ScanNCut, are designed to cut fabric. They can be used for quilting, appliqué, and even creating custom fabric stickers. Just be sure to use the appropriate settings and blades for fabric cutting.

What are some tips for achieving clean cuts with shape cutting machines?

+

To achieve clean cuts, ensure your machine is properly calibrated and your materials are secured tightly. Use the appropriate blade for the material you’re cutting, and consider using a cutting mat designed for your machine to provide a smooth cutting surface. Finally, ensure your design is free from any errors or imperfections before cutting.